1933 Pontiac Economy Eight

The Economy Eight series 601 was all new for 1933 and consisted of 7 body styles, the least expensive model being the roadster, with a list price of $585. Pontiac had not offered a roadster since 1930, which then cost $765 and was only available with a six cylinder engine. Pontiac prices were reduced to their lowest amount ever in 1933; the most expensive models, the convertible coupe and the 4 door sedan both carried a list price of $695, f.o.b. the factory in Pontiac, Michigan.

The series 601 model line consisted of the 4 passenger, rumble seat roadster, the 2 passenger standard coupe, the Sport Coupe and convertible coupe also featured rumble seats and 4 passenger capacity, while the 2 and 4 door sedans were 5 passenger jobs. New for 1933 was the 2 door Touring Coupe, which offered seating and an enclosed trunk compartment built onto the rear body, for 5 passengers and their luggage.

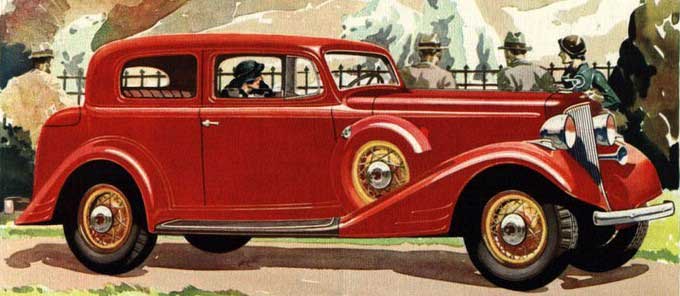

The all new bodies reflected modern, stream-line styling. The grille featured 27 vertical bars, vee-shaped and set a rakish angle. The standard single horn was chrome plated and carried beneath the drivers’ side headlamp. The hood had 4 nearly vertical louvers on either side, set well back on the panels near the cowl. Front and rear fenders were deeply skirted to minimize water splash and adorned with “speed-lines” stamped into the metal. Trailing from each wheel opening, the “speed-lines” complimented the rakish lines of the front grille, windshield and the pronounced “beaver-tail” at the bottom of the rear body. A single, drivers’ side tail lamp was standard equipment, gracefully extending on an elongated, horizontal pedestal. An optional matching tail lamp was available for the passenger side, which was also the location of the fuel

tank filler neck.

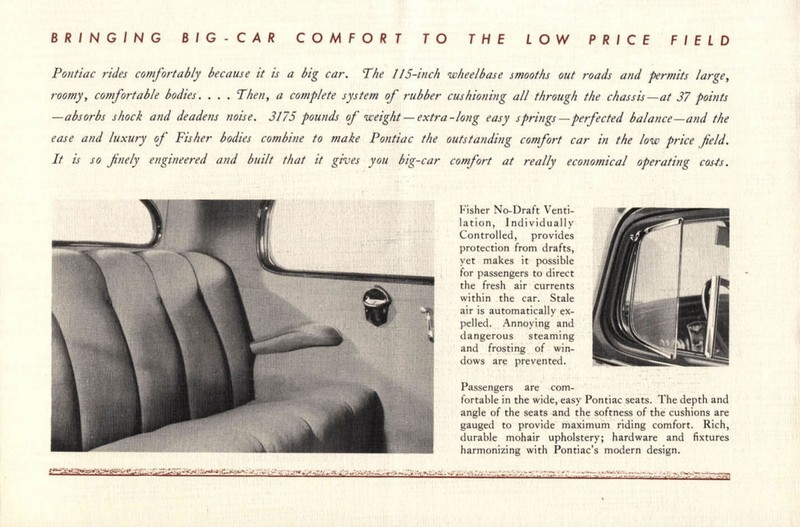

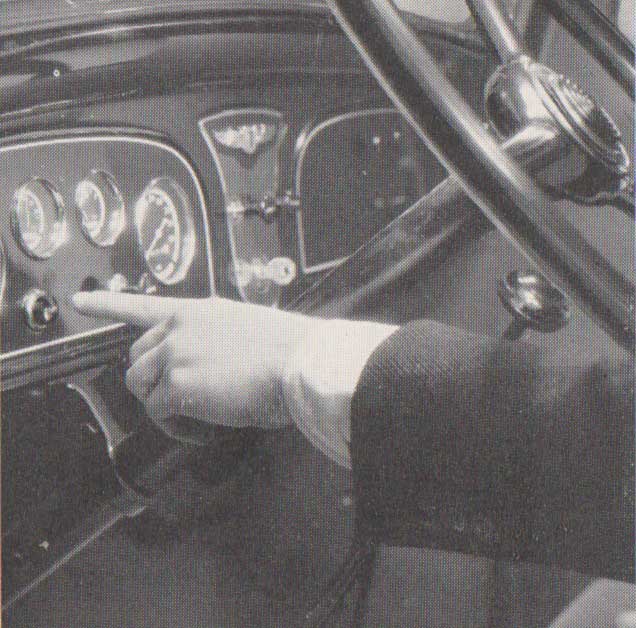

The Fisher bodies offered their patented No-draft Ventilation, individually controlled by the ventilator windows, these and the windshield were fitted with safety-plate glass. The interiors for enclosed models were upholstered in high quality mohair front and rear, the open cars got leather. The sedans were completely outfitted with a rear seat foot rest, lap-robe cord, ashtrays, arm rests, assist straps and a dome lamp. The front passenger compartment offered fore and aft adjustable seating and arm rests on both sides. The roadsters were fitted with side curtains to keep out inclement weather. All coupe and sedan doors were fitted with window regulators, storage pockets and inside door locks. When locked, the outside door handles were disconnected and gave when turned, thus preventing the door handle to be used to “force” the lock. A driver’s side sun visor and vacuum operated windshield wiper were standard equipment. The dashboard featured a passenger side glove compartment with a latching door. The instrument panel was fitted with a dial and pointer type speedometer, plus ancillary gauges for fuel, oil pressure, water temperature and ammeter. All gauges were white markings on black faces with indirect lighting for illumination at night. The central dashboard was trimmed with a winged 8 emblem above the ignition switch and knobs for the choke and throttle. New for 1933 were the push button starter control on the dashboard and the treadle-type accelerator pedal. The headlamp dimmer switch remained on the floorboard, along with the gearshift and hand brake levers which were centrally located.

Optional comfort accessories included an under-dash heater, a rear view mirror, a cigar lighter, a clock and a radio, with the antenna mounted under the running board.

The color palette for 1933 models offered 22 choices in total. There were standard color combinations according to body style, plus a wide array of optional combinations. Roadsters and convertible coupes came in Media Red with black fenders, red wheels and a red accent stripe, unless otherwise specified. The standard coupe and both 2 door sedans featured black bodies and fenders, black and red wheels and a red stripe. The Sport Coupe was black over Vineyard Lake Maroon, with black fenders and wheels and a red accent stripe. The 4 door sedan finish was Vendome Blue top and bottom, with black fenders and wheels and cream-colored stripe.

Kelsey-Hayes 40 spoke wire wheels mounting 5.50 x 17 tires came standard on all models, while disc wheels fitted with “balloon” tires were an available option. Indian head hub caps were standard, bright wheel trim rings were available. All models came with standard with a single spare tire, mounted on the rear body. Six-wheel equipment was available with side-mount spares carried on either front fender. Metal covers could be purchased to conceal the spare tire(s). A luggage rack replaced the rear spare on the 6 wheel jobs; an optional “trunk” for storage was also available on all but the Touring Coupe, which obviously had a trunk as part of the body.

The chassis was also new for 1933 and rode on a 115 inch wheel base. Mechanical brakes with 12 inch drums were fitted at all four corners; the hand brake actuated both front and rear wheels when applied. The rear axle was located by leaf springs and a torque tube, the only available ratio was 4.44:1. The transmission was synchronized on second and third gears and “freewheeling” continued as standard equipment. The solid front axle was of the reverse Elliot type, with leaf springs and Delco-Lovejoy shock absorbers. The rear suspension was also stabilized with hydraulic shock absorbers.

The really big news for 1933 was residing under the hood, a new straight eight. This engine replaced both the twin-head six, dating from Pontiac’s introduction in1926, and the limited production V-8, which was only used in early 1932. The new eight was the only engine available in any Pontiac, which made sense if you consider that Chevrolet and Plymouth were now both six cylinder automobiles and Ford’s V-8 debuted in 1932.

The Economy Eight series 601 was all new for 1933 and consisted of 7 body styles, the least expensive model being the roadster, with a list price of $585. Pontiac had not offered a roadster since 1930, which then cost $765 and was only available with a six cylinder engine. Pontiac prices were reduced to their lowest amount ever in 1933; the most expensive models, the convertible coupe and the 4 door sedan both carried a list price of $695, f.o.b. the factory in Pontiac, Michigan.

The series 601 model line consisted of the 4 passenger, rumble seat roadster, the 2 passenger standard coupe, the Sport Coupe and convertible coupe also featured rumble seats and 4 passenger capacity, while the 2 and 4 door sedans were 5 passenger jobs. New for 1933 was the 2 door Touring Coupe, which offered seating and an enclosed trunk compartment built onto the rear body, for 5 passengers and their luggage.

The all new bodies reflected modern, stream-line styling. The grille featured 27 vertical bars, vee-shaped and set a rakish angle. The standard single horn was chrome plated and carried beneath the drivers’ side headlamp. The hood had 4 nearly vertical louvers on either side, set well back on the panels near the cowl. Front and rear fenders were deeply skirted to minimize water splash and adorned with “speed-lines” stamped into the metal. Trailing from each wheel opening, the “speed-lines” complimented the rakish lines of the front grille, windshield and the pronounced “beaver-tail” at the bottom of the rear body. A single, drivers’ side tail lamp was standard equipment, gracefully extending on an elongated, horizontal pedestal. An optional matching tail lamp was available for the passenger side, which was also the location of the fuel

tank filler neck.

The Fisher bodies offered their patented No-draft Ventilation, individually controlled by the ventilator windows, these and the windshield were fitted with safety-plate glass. The interiors for enclosed models were upholstered in high quality mohair front and rear, the open cars got leather. The sedans were completely outfitted with a rear seat foot rest, lap-robe cord, ashtrays, arm rests, assist straps and a dome lamp. The front passenger compartment offered fore and aft adjustable seating and arm rests on both sides. The roadsters were fitted with side curtains to keep out inclement weather. All coupe and sedan doors were fitted with window regulators, storage pockets and inside door locks. When locked, the outside door handles were disconnected and gave when turned, thus preventing the door handle to be used to “force” the lock. A driver’s side sun visor and vacuum operated windshield wiper were standard equipment. The dashboard featured a passenger side glove compartment with a latching door. The instrument panel was fitted with a dial and pointer type speedometer, plus ancillary gauges for fuel, oil pressure, water temperature and ammeter. All gauges were white markings on black faces with indirect lighting for illumination at night. The central dashboard was trimmed with a winged 8 emblem above the ignition switch and knobs for the choke and throttle. New for 1933 were the push button starter control on the dashboard and the treadle-type accelerator pedal. The headlamp dimmer switch remained on the floorboard, along with the gearshift and hand brake levers which were centrally located.

Optional comfort accessories included an under-dash heater, a rear view mirror, a cigar lighter, a clock and a radio, with the antenna mounted under the running board.

The color palette for 1933 models offered 22 choices in total. There were standard color combinations according to body style, plus a wide array of optional combinations. Roadsters and convertible coupes came in Media Red with black fenders, red wheels and a red accent stripe, unless otherwise specified. The standard coupe and both 2 door sedans featured black bodies and fenders, black and red wheels and a red stripe. The Sport Coupe was black over Vineyard Lake Maroon, with black fenders and wheels and a red accent stripe. The 4 door sedan finish was Vendome Blue top and bottom, with black fenders and wheels and cream-colored stripe.

Kelsey-Hayes 40 spoke wire wheels mounting 5.50 x 17 tires came standard on all models, while disc wheels fitted with “balloon” tires were an available option. Indian head hub caps were standard, bright wheel trim rings were available. All models came with standard with a single spare tire, mounted on the rear body. Six-wheel equipment was available with side-mount spares carried on either front fender. Metal covers could be purchased to conceal the spare tire(s). A luggage rack replaced the rear spare on the 6 wheel jobs; an optional “trunk” for storage was also available on all but the Touring Coupe, which obviously had a trunk as part of the body.

The chassis was also new for 1933 and rode on a 115 inch wheel base. Mechanical brakes with 12 inch drums were fitted at all four corners; the hand brake actuated both front and rear wheels when applied. The rear axle was located by leaf springs and a torque tube, the only available ratio was 4.44:1. The transmission was synchronized on second and third gears and “freewheeling” continued as standard equipment. The solid front axle was of the reverse Elliot type, with leaf springs and Delco-Lovejoy shock absorbers. The rear suspension was also stabilized with hydraulic shock absorbers.

The really big news for 1933 was residing under the hood, a new straight eight. This engine replaced both the twin-head six, dating from Pontiac’s introduction in1926, and the limited production V-8, which was only used in early 1932. The new eight was the only engine available in any Pontiac, which made sense if you consider that Chevrolet and Plymouth were now both six cylinder automobiles and Ford’s V-8 debuted in 1932.

Ben Anibal received the design credit for the new Pontiac Eight, but his parameters were set by Charles “Boss” Kettering at General Motor’s Research Labs; and also Henry Crane, who was Alfred Sloan’s engineering advisor. Anibal was given a formidable task; design a strong, reliable engine, with smooth and quiet operating characteristics, which was capable of running at high speed for extended periods and was also inexpensive to manufacture! Alfred Sloan, General Motors’ marketing guru and current President, expected to offer buyers an eight cylinder automobile for just a few dollars more than those of the low-priced “big three”. Ben Anibal clearly met the goals set for him!

It’s not surprising that the new straight eight was an L-head design; this configuration had a couple of real advantages at this point in production automobile development. First, placing the valves in the block directly above the camshaft resulted in a lightweight, rigid valve-train with a minimum of moving parts. The lightweight valve and lifter permitted the use of valve springs with a minimum of pressure, which greatly reduced cam and lifter wear. L-head engines were also very quiet, since the valve mechanism with its necessary operating clearance, was buried deep within the engine block. The buying public already equated quiet operation with expensive, luxury automobiles and Sloan demanded this virtue for the new Pontiac. Anibal chose a more costly timing chain over a gear drive for the camshaft; it was not only quieter but more durable, too.

Advertising proclaimed it “the longest engine built with a 3 3/16 inch bore”! This extra length allowed for each cylinder to be completely surrounded by water for more reliable cooling. In addition to adequate water jackets, a distribution tube was installed that ran the full length of the engine. Supplied with coolant directly from the water pump, it eliminated hot spots within the engine. A thermostat with coolant bypass was also standard equipment, assuring a quick warm-up to operating temperature. Anibal’s engine requirements were the first priority, stylists later designed the automobile to house it.

The cylinder stroke was 3 ½ inches, very short for the time and a definite plus for reliability due to minimizing friction The cylinder block extended below the crankshaft centerline by 2 ½ inches, and 2 longitudinal ribs were cast into each side of the block for even further rigidity. The forged steel, fully counter-weighted crankshaft ran in 5 main bearings, and was both statically and dynamically balanced. The lubrication system was fully pressurized; including rifle-drilling the forged steel connecting rods. Pressure lubrication of the piston pins was another quality feature usually reserved for the most expensive cars. The oil pump was mounted outside of the pan for ease of access, and the only tubing connection in the entire lubrication system was that of the oil pick-up to the pump mount. The Delco ignition distributor was driven from the oil pump, the housing protruded from the block at an angle on the driver’s side. This allowed for cylinder head removal without disturbing the ignition timing, not a feature of Pontiac’s original six cylinder engine.

Anibal specified tin-plated, alloy iron pistons as opposed aluminum, this was done for two reasons. First, iron pistons can be fitted very tightly to the cylinder bores, since the expansion rate is the same as that of the engine block. This means quiet operation and minimizes oil consumption. Secondly, these were the days before quality, detergent oils and full-flow filtration systems, so the durability of iron far exceeded that of aluminum. The pistons carried 3 compression rings above the piston pin, and the oil ring at the bottom of the skirt. This was done to retain oil when the engine was stopped, minimizing piston and cylinder wear upon start-up. The tin-alloy electro-plating of the pistons was a proven Pontiac practice that originated with the six cylinder engine, as were the precision balance of all the reciprocating parts and the fitting of a harmonic balancer to the crankshaft. These are all extra-cost features that Pontiac offered to improve the durability and value of their product.

An AC fuel pump with filter was used, drawing from an 18 gallon tank. The fuel line was mounted outside of the frame rail and away from exhaust heat to prevent vapor lock. A Carter W1 downdraft carburetor provided the mixture; it featured a triple-venturi, economizer and an acceleration pump. The carburetor was also fitted with an air cleaner and silencer as standard equipment. The intake manifold was fitted with a thermostatically controlled heat riser to warm the mixture for proper combustion and smooth running during warm-up.

The new straight eight displaced 223 cubic inches and produced 77 horsepower at 3,600rpm. The compression ratio was 5.7:1 and the combustion chambers were a General Motors Research design for maximum power with minimal spark knock. A top speed of 78 miles per hour was claimed for the new Pontiac, while maintaining the operating economy of many six cylinder automobiles. Production began in December, 1932 and ended on October 6th, 1933 with 90,198 vehicles manufactured.

The introduction of the straight eight gave Pontiac a solid hold on the huge market segment priced just above the “big three”…a sales position they would dominate through 1954, when the venerable straight eight engine was phased out of production.

It’s not surprising that the new straight eight was an L-head design; this configuration had a couple of real advantages at this point in production automobile development. First, placing the valves in the block directly above the camshaft resulted in a lightweight, rigid valve-train with a minimum of moving parts. The lightweight valve and lifter permitted the use of valve springs with a minimum of pressure, which greatly reduced cam and lifter wear. L-head engines were also very quiet, since the valve mechanism with its necessary operating clearance, was buried deep within the engine block. The buying public already equated quiet operation with expensive, luxury automobiles and Sloan demanded this virtue for the new Pontiac. Anibal chose a more costly timing chain over a gear drive for the camshaft; it was not only quieter but more durable, too.

Advertising proclaimed it “the longest engine built with a 3 3/16 inch bore”! This extra length allowed for each cylinder to be completely surrounded by water for more reliable cooling. In addition to adequate water jackets, a distribution tube was installed that ran the full length of the engine. Supplied with coolant directly from the water pump, it eliminated hot spots within the engine. A thermostat with coolant bypass was also standard equipment, assuring a quick warm-up to operating temperature. Anibal’s engine requirements were the first priority, stylists later designed the automobile to house it.

The cylinder stroke was 3 ½ inches, very short for the time and a definite plus for reliability due to minimizing friction The cylinder block extended below the crankshaft centerline by 2 ½ inches, and 2 longitudinal ribs were cast into each side of the block for even further rigidity. The forged steel, fully counter-weighted crankshaft ran in 5 main bearings, and was both statically and dynamically balanced. The lubrication system was fully pressurized; including rifle-drilling the forged steel connecting rods. Pressure lubrication of the piston pins was another quality feature usually reserved for the most expensive cars. The oil pump was mounted outside of the pan for ease of access, and the only tubing connection in the entire lubrication system was that of the oil pick-up to the pump mount. The Delco ignition distributor was driven from the oil pump, the housing protruded from the block at an angle on the driver’s side. This allowed for cylinder head removal without disturbing the ignition timing, not a feature of Pontiac’s original six cylinder engine.

Anibal specified tin-plated, alloy iron pistons as opposed aluminum, this was done for two reasons. First, iron pistons can be fitted very tightly to the cylinder bores, since the expansion rate is the same as that of the engine block. This means quiet operation and minimizes oil consumption. Secondly, these were the days before quality, detergent oils and full-flow filtration systems, so the durability of iron far exceeded that of aluminum. The pistons carried 3 compression rings above the piston pin, and the oil ring at the bottom of the skirt. This was done to retain oil when the engine was stopped, minimizing piston and cylinder wear upon start-up. The tin-alloy electro-plating of the pistons was a proven Pontiac practice that originated with the six cylinder engine, as were the precision balance of all the reciprocating parts and the fitting of a harmonic balancer to the crankshaft. These are all extra-cost features that Pontiac offered to improve the durability and value of their product.

An AC fuel pump with filter was used, drawing from an 18 gallon tank. The fuel line was mounted outside of the frame rail and away from exhaust heat to prevent vapor lock. A Carter W1 downdraft carburetor provided the mixture; it featured a triple-venturi, economizer and an acceleration pump. The carburetor was also fitted with an air cleaner and silencer as standard equipment. The intake manifold was fitted with a thermostatically controlled heat riser to warm the mixture for proper combustion and smooth running during warm-up.

The new straight eight displaced 223 cubic inches and produced 77 horsepower at 3,600rpm. The compression ratio was 5.7:1 and the combustion chambers were a General Motors Research design for maximum power with minimal spark knock. A top speed of 78 miles per hour was claimed for the new Pontiac, while maintaining the operating economy of many six cylinder automobiles. Production began in December, 1932 and ended on October 6th, 1933 with 90,198 vehicles manufactured.

The introduction of the straight eight gave Pontiac a solid hold on the huge market segment priced just above the “big three”…a sales position they would dominate through 1954, when the venerable straight eight engine was phased out of production.

Magazine Ad Links: Sounds Unbelievable New Car in the Low Price Field